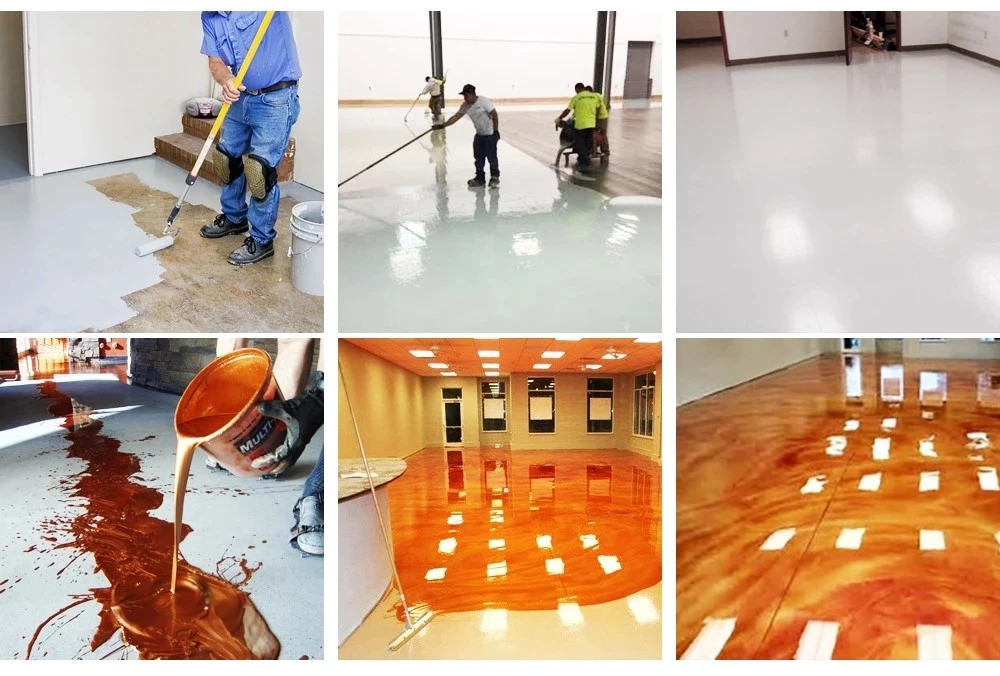

A variety of possible epoxy floor solutions allows you to pour the composition in any room: kitchen, bedroom, living room, hallway, bathroom, terrace, balcony, etc. The surface will wash perfectly, will not let water through, and will cast a glossy shine.

Industrial Floors: –

The increased durability allows them to be used on objects with high traffic: sports facilities, hospitals, educational institutions. The base is very resistant to abrasion, tearing, easy to clean, non-slip. The main thing is that the mixture can be laid directly on old concrete.

Concrete Impregnation: –

If necessary, reinforce the concrete industrial floor, use epoxy impregnation. It penetrates 1-5 mm in depth, filling cracks and pores. The concrete surface is dust-free and more durable.

Thin Layer Coating: –

If it is necessary to increase the strength of the surface, the epoxy resin is applied in a layer up to 1 mm. So, you can get a hygienic base for a room with average loads and normal humidity levels. Replacement will not be required for 4 years.

Self-Leveling Floor: –

The resin is applied in a layer up to 5 mm thick on old concrete substrates. This solution is applicable when it is necessary to create an aesthetically pleasing floor that is impervious to water, resistant to loads and impacts, with a sliding effect.

When the manufacturer adds various additives to the dry building mixture, mixtures are obtained with several additional qualities required in a particular room.

Why Epoxy Flooring Tiles?

In every house and apartment, at some point, major repairs cannot be avoided. This also includes the renovation of the flooring. Before you can install a new floor, you usually need to remove the old one first. Especially old bathroom tiles are often difficult to remove and often have to be broken with great effort. The bathroom needs not only a new floor covering but also a waterproof and waterproof floor covering. A commercial epoxy floor is a good choice for new coatings on old tiles. The epoxy resin consists of two components: resin and hardener. After you have mixed these two components according to the instructions, you can apply epoxy as a coating.

Why is Epoxy Flooring So Popular?

The epoxy floor is due to the huge number of positive qualities and advantages over other polymer coatings. Epoxy coating is widely used due to the environmental friendliness of the coating, which is used in schools, kindergartens, universities, military buildings, shops, and of course apartments. Apart from all this, they are seamless and easy to clean. Due to its abrasion resistance, self-leveling floors based on the epoxy resin are used in parking lots, car services, garages, warehouses. Epoxy flooring has resistance to shock and mechanical stress, which makes such a coating preferable for industrial premises, and, of course, resistance to chemical and biological substances makes such a coating the best option for the chemical, pharmaceutical, and food industries. Different types of epoxy coatings are used when installing a polymer floor covering, depending on the load, budget, etc.

How To Prepare the Base For Epoxy Flooring?

The best surface for epoxy glue is concrete. If the surface is made of a different material, then a liquid floor can also be poured onto it, even if it is a tile.

The only surface that may become a problem in the future is wood, as it is prone to deformation. It is also important that the subfloor is relatively flat and dry. For every 2 meters, a deviation of up to 2 mm horizontally is allowed.

How to Choose An Epoxy Floor?

When choosing epoxy self-leveling floors, you should pay attention to two factors. First, the composition of the emulsion must be suitable for future use. Depending on the expected mechanical or chemical stresses, an appropriate epoxy must also be selected. The second factor is the design decision. If we are talking about covering industrial structures, then there is no need for excessive sophistication. However, for private houses and especially for restaurants and cafes, it is very important to choose the right color palette and floor pattern. For bathrooms, 3D effects have recently become popular. You can use photographs, but you should be careful with them because it will not be possible to change the drawing over time

Why Epoxy Self-Leveling Floors Are Good?

The excellent mechanical strength of the coating, including resistance to abrasion, abrasion, crumbling and cracking. The bottom line is that such a floor can last 3 -4 decades. Epoxy coating is not afraid of almost any chemical reagents, even the most aggressive ones – solvents, technical fluids. The highest water resistance – floor does not absorb water and does not pass, becoming thereby, excellent waterproofing premises. The epoxy coating is immune to temperature extremes and the damaging effects of UV rays. The material is distinguished by its high purity from the point of view of ecology, and does not pose any fire hazard – it is non-flammable. for example, polyurethane is not accompanied by persistent unpleasant odors. Epoxy coating, subject to technological requirements when pouring, gives a perfectly flat floor plane, with the required gloss, matte, or roughness.

What Are the Properties of Epoxy Floors?

· Epoxy painting company is a colored, two-component epoxy system, generally solvent-free.

· With the addition of quartz sand to the mixture, with an average particle diameter of up to 0.4 mm, a self-leveling mortar is created, which is ideal for coating industrial concrete floors.

· The epoxy coating has high adhesion to concrete, cement screed, and, in general, to surfaces based on mineral and cement materials.

· The epoxy coating has high mechanical strength: hardness combined with relative elasticity and abrasion resistance.

· Epoxy coating has waterproofing, chemical resistance to acids, alkalis, solvents, fuels and lubricants, seawater, and detergents.

- The epoxy coating makes it possible to apply a wide range of colors and create a variety of surface configurations.

What tools are needed to apply epoxy concrete flooring?

Epoxy flooring requires tools. Not to say that you need something special, but the list is solid. You can’t do without them.

- Wet walkers. These are boots with soles on rods. They leave no trace. You have to step over them, not slide or shuffle. If you drag them over the surface, stripes remain.

- Primer rollers. The pile should be of polyamide or nylon 10-12 mm long. It is possible to apply primer with a flat trowel, but this requires some skill.